Steel fabrication is the procedure behind the creation of a wide variety of products, including survival bunkers and storm shelters. It involves many different techniques and requires pinpoint accuracy, but it’s the most efficient way to turn raw steel into complex structures.

Here’s a full breakdown of the steel fabrication process and its many benefits — plus the advantages of having a steel bunker over other materials.

A Simple Breakdown of Steel Fabrication

In a nutshell, steel fabrication is the practice of creating steel items through secondary manufacturing methods. While primary steel manufacturing takes place in steel mills and foundries, steel fabrication takes place in your average warehouse or assembly plant. This industry is more efficient than ever thanks to advancements in automated manufacturing.

Steel fabrication takes semi-finished steel items and turns them into finished products in a handful of ways:

- Cutting: Technicians fracture the steel with a saw, drill or grinder into the desired shape, leaving small pieces called “chips” behind. Chips are recycled or repurposed for other items.

- Welding: Instead of splitting up the steel, welding fuses two or more parts together through heat and pressure. Gas metal arc welding is the most common type.

- Bending: Workers use a press brake tool to force steel sheets or rods into a predetermined shape.

- Drilling: Drilling is a specific cutting technique that bores holes with specific dimensions into the steel, which requires a high-speed steel drill bit.

- Bolting: After drilling the required holes, two or more steel parts may be bolted together with semi-permanent joints.

- Coating: Metal coating is often applied to steel surfaces as a protective barrier against oxidation, which causes rust and corrosion. The process usually consists of hot-dip galvanizing or thermal spraying.

Each of these techniques has its place, but cutting is usually the primary steel fabrication method because pre-fabricated steel often gets split into multiple units. Bandsaws are the main tools for the job, as there are many specialty saws that can cut through heavy steel grades like a hot knife through butter.

Steel fabrication isn’t always the same as metal fabrication. The latter process deals with raw metals like copper and titanium, but steel is an alloy made from iron ore. Alloys go through a more intense fabrication because they’re stronger than naturally occurring metals. It starts with the purification of iron ore, followed by the addition of carbon to lower its melting point.

Other common alloy elements that manufacturers add to steel include aluminum, chromium, nickel, copper and manganese. They all have varying effects, but their overarching purpose is to make steel stronger and yet more malleable.

Benefits of Steel Fabrication

When it comes to underground shelters, fabricated steel is the best material hands down. A steel bunker is the safest place someone can be during an emergency event. Here are some of the biggest reasons why steel fabrication is so valuable for bunker construction.

Saves Time and Money

Fabricated steel is much easier to install than other metals during construction. The steel already has the required dimensions to seamlessly fit within the building’s infrastructure. It’s much easier to prepare the steel in a controlled environment and transport the finished parts to the worksite. Technicians can prepare each part with pinpoint accuracy, allowing for greater customization.

Steel fabrication is an essential component of a greater trend called prefabricated construction. With “prefab” construction, workers develop sections of the building off-site and transport them to the site for assembly later on. This new method of construction makes it much easier to add steel panels, beams, trusses and fasteners.

Enhances Steel’s Durability

Steel is already one of the most durable and long-lasting metals available, which is why it’s so popular in construction. Steel fabrication enhances these qualities even further. Technicians can cut, bend and weld the steel into exact shapes, drill or bolt parts together and add protective coatings.

These improvements make steel the superior material for underground structures because it can withstand cracks, corrosion, moisture and harsh weather. Buildings with fabricated steel are more likely to last for their expected lifespans and less likely to require frequent maintenance.

Better for the Environment

Fabricated steel is also the best choice for the environment. It’s corrosion resistant, which means it takes a long time to decompose and seep into the earth at landfills. Buildings with fabricated parts also tend to produce less construction waste — especially timber, concrete and steel. Waste is the biggest contributor to the construction industry’s overall pollution.

Steel is also 100% recyclable, meaning that builders can repurpose it again and again without sacrificing its durability. In theory, a building’s panels and beams could consist entirely of recycled steel with no difference in quality.

Advantages of Steel Bunkers

Underground shelters are either made of steel or concrete. Although concrete is usually more affordable and easier to install, steel has some more important advantages. Here are the most relevant reasons why fabricated steel is the best choice.

Unmatched Flexibility

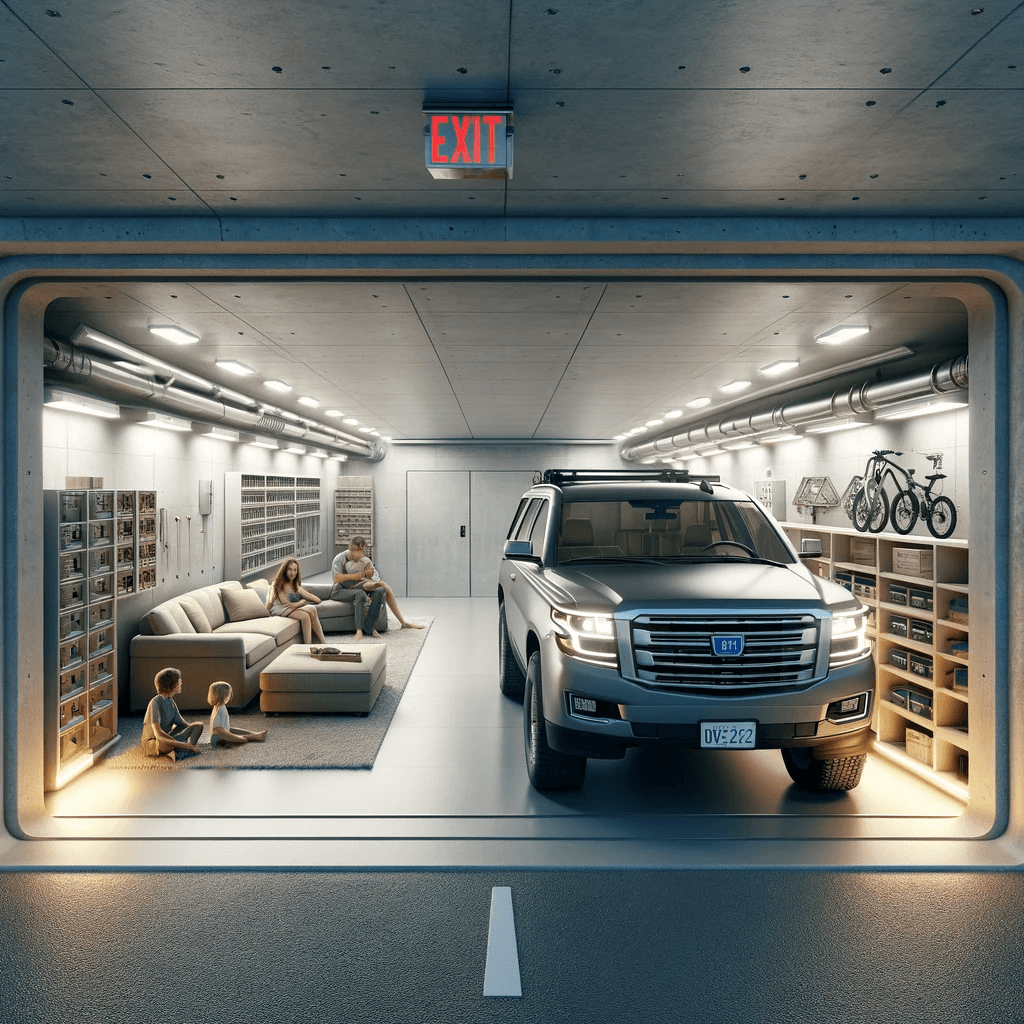

Bunkers come in many shapes and sizes. There is no one-size-fits-all solution because every family has different needs and preferences. That’s the biggest reason why steel is the perfect material. Steel bunkers are fully customizable for both security and luxury, allowing homeowners to specify every detail and make changes during construction as necessary.

For example, a family might need handicap accessibility for an elderly or disabled relative. They might also want to expand the bunker in the future if they plan on having more children. Whether they want to add another bedroom, kitchen, bathroom or recreation center, these customization options are the easiest to pull off with steel.

Resilient to the Elements

The strongest survival bunkers are made of quarter-inch carbon plate steel, which is two times thicker than federal requirements for steel structures. This level of thickness makes bunkers twice as resilient against the elements, including earthquakes. It would take an apocalyptic disaster to remove a steel bunker from its foundations.

Steel plates also usually have industrial rubber coatings that improve the shelter’s longevity. The coating provides extra protection against all forms of corrosion. This added layer is a huge advantage for underground shelters because they’re supposed to support long-term residency. Occupants might have to stay there for years, so they need all the protection they can get.

Steel’s anti-corrosive quality also neutralizes the greatest nonlethal threat to underground bunkers — moisture. Over time, rain and groundwater can corrode concrete and other metals, leading to leaks, mold and significant foundational damage. Steel doesn’t absorb any water, so the bunker’s occupants never have to worry about these problems.

Those who are willing to pay extra can also request galvanized steel, which has an extra coating of zinc. Galvanized steel is more resistant to rust than regular steel, and it can also protect against fire more effectively. Fire resistance is a must-have for bomb shelters in particular.

Fabricated Steel is the Only Real Option

Based on all of these benefits of fabricated steel — both in terms of construction and long-term performance — this material is the only real option for survival bunkers. No other material can offer the same combination of durability and flexibility.

While it’s not the cheapest option, money shouldn’t be the deciding factor when preparing for potential disasters. The deciding factor should be which material gives the best chance of survival, and fabricated steel is the clear answer.

Get involved!

Comments